Introduction

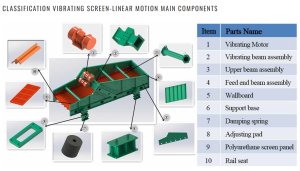

GN SEPARATION offers an efficient and reliable solution for material classification with its Classification Vibrating Screen – Linear Motion. Designed to meet the needs of various industries, this equipment is widely applied in the classification and screening of iron ore, coal, non-ferrous metal ore, building materials, chemical industry, and more. With advanced design, robust structure, and customizable features, GN Classification Vibrating Screen delivers high performance, large processing capacity, and long service life.

Technical Design and Advanced Analysis

The GN Classification Vibrating Screen is built using cutting-edge technologies to ensure structural stability, energy efficiency, and exceptional performance:

- Finite Element Analysis & Anti-Fatigue Design

- The equipment undergoes finite element and anti-fatigue analysis to optimize structural strength, reduce stress, and ensure reliability under demanding conditions.

- The wallboard is constructed without welding, utilizing HUCK rivet hydraulic tension assembly to eliminate welding residual stress and material defects.

- Wear and Corrosion Resistance

- Fluids touching parts and wear-prone components are coated with polyurea using an advanced spraying system, ensuring excellent corrosion resistance, erosion resistance, and durability.

- Heat Treatment for Longevity

- Post-weld heat treatment is applied to the main components, effectively eliminating residual stress and enhancing the service life of the equipment.

Operational Principle

The GN Classification Vibrating Screen uses two powerful vibrating motors to generate linear motion. Here’s how it works:

- The screen body moves linearly due to reverse self-synchronization of the motors.

- This motion causes the screen panel to vibrate, transferring force to the materials on the screen surface.

- Materials are thrown up and layered on the screen surface, then graded according to particle size.

- The materials are fed continuously from the trough, screened, and discharged into respective outlets above and below the screen, ready for the next processing stage.

- The vibration angle can be customized based on material properties, ensuring optimized processing capacity and material flow speed.

Technical Parameters

Below are the technical specifications of GN SEPARATION’s Classification Vibrating Screen:

| Model | GNLMP1236 | GNLMP1536 | GNLMP1836 | GNLMP1848 | GNLMP2448 |

|---|---|---|---|---|---|

| Screen Area | 4.32 m² | 5.4 m² | 6.48 m² | 8.64 m² | 11.52 m² |

| Vibration Angle | 38–52° | 38–52° | 38–52° | 38–52° | 38–52° |

| Frequency | 16 Hz | 16 Hz | 16 Hz | 16 Hz | 16 Hz |

| Power | 2×2.9 kW | 2×2.9 kW | 2×4.5 kW | 2×5 kW | 2×7 kW |

| Double Amplitude | 4–6 mm | 4–6 mm | 4–6 mm | 4–6 mm | 4–6 mm |

| Screen Opening | 0.2–25 mm | 0.2–25 mm | 0.2–25 mm | 0.2–25 mm | 0.2–25 mm |

| Dry Capacity | 5–18 m³/h | 6–20 m³/h | 8–28 m³/h | 10–40 m³/h | 18–80 m³/h |

| Installation Angle | ±4° | ±4° | ±4° | ±4° | ±4° |

Note: Specifications are for reference and may be customized based on customer requirements. Handling capacity can vary significantly with material properties.

Key Features and Advantages

- Customizable Design

- Screen size, inclination angle, and vibration angle can be tailored to meet specific material and process requirements.

- Modular Screen Panels

- The polyurethane screen panels are modular, making replacements versatile and convenient.

- Optimized Screening Efficiency

- The plane design maximizes the effective screening area, ensuring thorough screening and grading of materials.

- Low Noise & Vibration Damping

- Equipped with rubber damping springs, the machine offers excellent vibration isolation, low noise, and stable mechanical performance.

- High Capacity & Efficiency

- Designed for large processing capacities with stable and efficient operation under various conditions.

- Durable Structure

- High-quality steel with impact toughness and cold bending properties ensures durability and reliability.

Applications Across Industries

GN Classification Vibrating Screen is ideal for:

- Mining: Iron ore, coal, non-ferrous metals.

- Building Materials: Aggregates, sand, cement.

- Chemical Industry: Screening various chemical raw materials.

- Other Materials: Applications requiring precise screening and classification under corrosive or high-wear environments.

Conclusion

GN SEPARATION’s Classification Vibrating Screen – Linear Motion delivers superior performance, durability, and flexibility for a wide range of industries. With its robust structure, advanced design, and customizable features, it ensures efficient material classification and screening while meeting the most demanding operational requirements.

Contact GN SEPARATION today to learn more about how our equipment can optimize your processes!

GN SEPARATION looks forward to working with you.

For further inquiries or technical support, feel free to contact us!