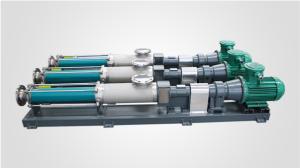

In the world of material transfer, efficiency, reliability, and product integrity are paramount. At GN Separation, we pride ourselves on delivering cutting-edge solutions to address the diverse needs of industries worldwide. Today, we’re thrilled to introduce our latest innovation – the GNG series Progressive Cavity Pump, also known as the single screw pump.

The GNG series Progressive Cavity Pump represents a significant advancement in material transfer technology. It comprises a helical rotor turning inside a helical stator, facilitating the seamless transfer of materials from intake to discharge without degradation. This unique design ensures that the product’s shape and volume remain unchanged throughout the pumping process, making it an ideal choice for feeding decanter centrifuges.

What sets the GNG series Progressive Cavity Pump apart is its exceptional strength, durability, and reliability. Designed to withstand pressures of up to 6 bar, the pump body and transmission parts are engineered to deliver unparalleled performance in even the most demanding environments. Whether it’s sludge transportation, dosing, or continuous operation, the GNG series pump rises to the challenge, ensuring stable and unmanned long-term operation.

Key features of the GNG series Progressive Cavity Pump include:

- Robust Construction: The pump stator rubber is securely bonded to the outer casing, eliminating seams, pores, or cracks that could compromise performance. Constructed from high-quality materials such as SBBPF, the stator boasts a design lifespan of over 10,000 hours under specified conditions.

- Material Versatility: Depending on the application and material being transferred, the pump rotor can be crafted from stainless steel or hard alloy material with special anti-abrasion and corrosion-resistant properties. This ensures optimal performance and longevity, even when handling corrosive or abrasive substances.

- Compact Design: The gear reducer selected for the GNG series pump is compact and integrated with the motor, offering space-saving benefits without sacrificing power or efficiency. Compatible with various power supplies ranging from 380V/460V to custom configurations, the motor ensures seamless operation across different frequency ranges.

The versatility of the GNG series Progressive Cavity Pump makes it suitable for a wide range of industries, including:

- Chemical Industry: From polymers and resins to acids and alkalines, our pump can handle a diverse range of chemical substances with ease.

- Mining Industry: Whether it’s slurries or explosive preparations, our pump excels in transferring materials used in mining operations.

- Paper Industry: Coating colors, dyes, and additives – our pump is trusted by leading paper manufacturers for efficient material transfer.

- Meat Industry: From pet food to fatty products, our pump ensures precise dosing and transfer of materials critical to the meat processing industry.

- Sugar and Beverage Industries: Molasses, syrups, juices, and more – our pump is the preferred choice for transferring ingredients and additives in sugar and beverage production.

In conclusion, the GNG series Progressive Cavity Pump represents a paradigm shift in material transfer technology. With its robust construction, versatile design, and unmatched reliability, it’s poised to redefine how industries transfer materials for years to come. Experience the future of material transfer with GN Separation’s GNG series Progressive Cavity Pump – where efficiency meets innovation.

For more information or to schedule a demonstration, visit our booth at ASIA Water 2024 or contact us today.