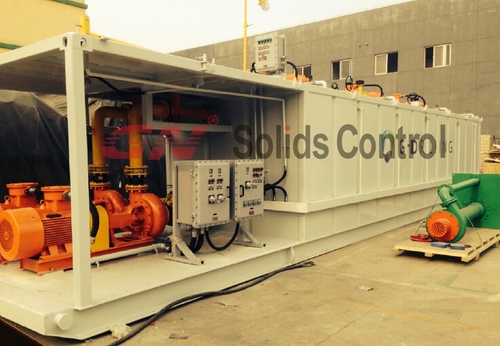

The drilling mud system processing sewage slurry ability big, the biggest slurry capacity of 250 m3 / h, purification desanding efficiency, separation size d50 = 0.030 ㎜. Vibrating screen low failure rate, simple operation, easy installation, use and maintenance. Advanced way of linear vibration screening out the ballast materials have very good dehydration effect. Adjustable vibration force of vibrating sieve, sieve surface Angle and mesh size in the various stratum can keep a good screening effect. Vibrating screen, high screening efficiency, and can be adapted to the various drilling rig in different formation pore penetration. Vibration motor, high power factor, low energy consumption, energy saving effect is remarkable. Vibrating screen operation low noise, which is beneficial to improve the working environment. Resistant to abrasion of centrifugal slurry pump with advanced structure, high degree of generalization, reliable operation and convenient installation and maintenance, etc; Thicker bearing grinding and with heavy bracket to make it suitable for conveying strong abrasion, high concentration of slurry for a long time.

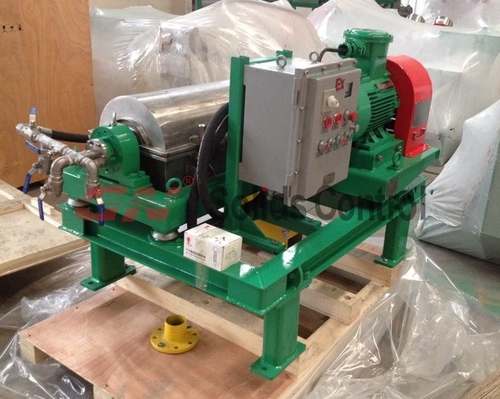

GN USA cuttings dryer functions within Venezuela, other than centrifuge decanter, all of us also provide shale shaker, dirt solution, centrifugal pump motor, this kind of type of solids manage tools function within Venezuela along with other South usa nations. The actual centrifuges tend to be delivered having a group which could change the actual elevation. Whenever this reached website, the consumer require to create a brand new remain to achieve the centrifuge upon, as well as make use of mounting bolts to repair all of them collectively. Additionally the consumer require to create a brand new lengthy solids release trough as well as use it the actual higher remain, exact same using the liquids electric outlet.

Design novel liquid level automatic balance device can not only maintain stability of the slurry storage tank liquid level, also can realize mud repeated processing, to improve the quality of purification. Unique recoil device can effectively prevent the slurry storage tank silt sand pulp, to maintain long-term normal operation. cuttings dryer’s working principle: by reverse circulation sand and gravel pump suction at the bottom of the bore of the unclean pulp through the total into the slurry pipe (1) to the mud purification device screen diction, by its vibration screening particle size in 3 separate ㎜ above the slag material. After coarse sieve screening of mud into the mud slurry storage tank (3) of the purification device, by the mud purification device of slag pulp pump (4) from the slot suction slurry, in the pump outlet has certain energy storage mud slurry hose from the hydrocyclone [5] the tangential into pulp inlet, through the hydrocyclone separation, fine particle size of mud by grit mouth out of the bottom of cyclone in fine screen [6]. A drier after fine sieve dehydration screening, fine design material, through the fine screen filter mud again return to the slurry storage tank