1.1 Inida MEDICINE & MEDICAL EQUIPMENTS PATHOLOGY CATEGORY project introduction

1.1 The Centrifuge design Bench Top Maximum RPM with no load 6000, Number of steps of RPM Variation available in the settings (correspondingly RCF also varies) 100 RPM setting accuracy plus minus 5% .Type of Motor Brushless.Type of lid lock Electronic lid locking with automatic lid opening at end of run Maximum Noise level when working at 1 meter distance in db 65 Ambient operating Temperature range in Degree centigrade Celsius and humidity range 0 to 50 and Relative humidity 15 to 90% .Rotor imbalance diagnostics and automatic stop if required .No of acceleration and deceleration profiles in built for rotor speed while automatic braking. Acceleration & Deceleration time to be less than 15 sec

1.2 Maximum timer set point 60 minutes Parameters to be displayed by the digital display RPM, RCF, set time, Run time, Rotor running indication, imbalance. if any Speed controller Microprocessor controlled pre-programmed speed controller which can control RPM as well as RCF Speed Control tolerance in case of set speed (Plus minus RPM) in percentage 20 Temperature controller Microprocessor based PID Digital temperature controller cum Indicator, (With LCD Display) to control the Temperature from +40 to -20℃

1.3 Type of Tubes which can be used with centrifuge machine Polypropylene Centrifuge tubes and Glass centrifuge tubes. Size of rotor supplied with centrifuge in ml.Maximum RCF 4800 Refrigerant should be CFC free .Temperature of refrigerator in degree Celsius 0 to 40 and relative humidity is 15 to 80% Cooling arrangement.

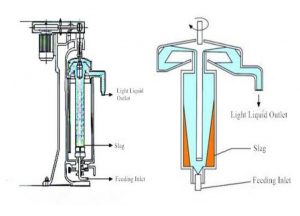

2.GN High Speed Tubular Centrifuge features and Advantages

2.1GN High Speed Tubular Centrifuge is a kind of fine separation equipment, which is especially suitable for the solid-liquid separation of suspensions with thin concentration, fine particles and small solid-liquid weight difference, or liquid-liquid-solid separation. It is necessary equipment for Industries of pharmaceutical, food, chemical, and biological products, fermentation broth, beverages, blood products, etc. Its working principle is based on the centrifugal force to make the materials of different specific gravity receive different forces, so as to achieve the purpose of separation.

2.2 High Speed Tubular Centrifuges is artificial slag removal equipment, and the processing capacity is limited, so it is generally used for working conditions with low solid content and relatively small processing capacity.