1. Project Description

1.1 LeangEy from B Scientific Instrument.Currently, we have a collaboration with the University that wishes to use the hydro-extractor to remove extra oil or water from food materials.Therefore, please let us know if you have distributors in Cambodia that can supply this product.

1.2 It is suitable for small batch production or laboratory sample test. Whole machine is made of high quality stainless steel, can get different grinding fineness by replacing the stainless steel sieves.Function of The hydro extractor helps remove extra oil or water from food materials.

Important features:Time controller and Centrifuge speed controller.Required machine Material:Stainless steel 304-316 made by material which resistant with high salt content sample.

Capacity10-15kg per batch.Voltage220V.Power 4KW.Size:38×30×21mm.Speed adjustment range:100-5000rpm.Timing control range:1 – 6000 min.Screen size(basket size):0.1mm, 0.5mm, 1.0mm, 1.5mm, and 2.00mm.Power Source:Electric

2.The GN Disc separator description and technical parameters

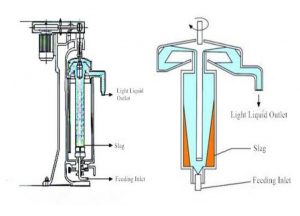

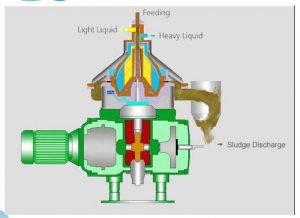

2.1 GF model: GN 3 phase disc stack separator is a high-speed, stable, sealed, efficient, and automatic slag discharge 3 phase separation equipment. It is widely used for liquid, liquid, solid 3-phase separation or liquid-liquid separation. The 2-phase solid-liquid separation disc separator has only one liquid discharge port and one slag discharge port, while the 3-phase disc separator has two liquid discharge ports and one slag discharge port, which can separate two liquids with different specific gravity at the same time. It can also discharge solid phase materials. Compared with the 3 phase decanter centrifuge, the 3 phase disc separator has larger rotation speed and G force.

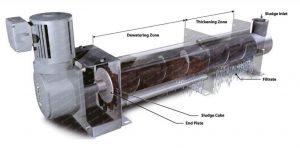

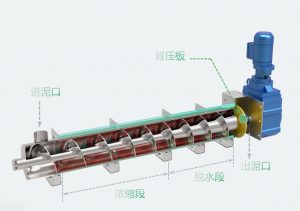

2.2 The 3 phase decanter centrifuge usually has a separation factor of about 3000G, while the 3 phase disc stack separator G force is up to 12000G. Therefore, the 3 phase disc separator can more thoroughly separate liquids with different specific gravity and the liquid phase discharged is more clarified. However, compared to 3 phase decanter centrifuges, 3 phase disc separator is more used to separate materials containing fine particles, with less solids content. So before entering the 3 phase disc separator, the material can separated by the decanter centrifuge for pre-stage separation to reduce the solids content and remove big particles.

犀利士5mg

犀利士5mg

” />