Foreword

As globalization continues to evolve, the demand for efficient and reliable pump technology in the logistics and industrial transportation sectors is steadily increasing. GN Separation, an experienced company in the field of solid vacuum pumps and transportation conveyingequipment, has recently achieved further success in the transportation of polypropylene slurry projects in Europe, adding valuable experience to our service records in the European region.

European Case Analysis

Recently, GN Separation’s solid vacuum pumps were sold to Europe, and the customer’s choice has demonstrated the superior performance of GN Separation’s solid vacuum pumps in the transport of polypropylene slurry. The efficient and stable operation of the pump allows manufacturers to smoothly transport raw materials, thereby improving production efficiency. The outstanding performance of GN Separation’s solid vacuum pump in the transport of polypropylene slurry in Europe demonstrates its wide-ranging potential applications in the industrial sector. Its advanced technology and design make it the preferred choice for handling solid particle media, providing a reliable and efficient pump solution for industrial production.

What is Polypropylene Slurry?

Introduction to Polypropylene Polypropylene (PP) is a thermoplastic polymer belonging to the category of synthetic resins. It possesses good mechanical properties, chemical stability, and excellent processing performance, making it widely used in various industries and daily life. Polypropylene is known for its lightweight, corrosion resistance, and good electrical insulation properties, suitable for manufacturing various plastic products.

- Overview of Polypropylene Slurry Polypropylene slurry is a mixture formed by suspending polypropylene particles in a liquid medium. This slurry is commonly used as a raw material for producing polypropylene fibers, plastic products, packaging materials, and more. The characteristics of polypropylene slurry depend on the size of particles, concentration, and other additives in the suspension.

- Characteristics of Polypropylene Slurry

Adjustable Concentration: The concentration of polypropylene slurry can be adjusted to meet the specific production requirements for different products.

Particle Size Distribution: Controlling the uniformity and size of particles is crucial for both the production process and the final product’s performance.

Rheological Properties: The rheological properties of polypropylene slurry directly impact its processing performance on the production line, including extrusion, injection molding, and other processes.

Chemical Stability: Polypropylene itself has excellent chemical stability, allowing polypropylene slurry to maintain its performance in various environments.

- Applications of Polypropylene Slurry

Textile Industry: Used for producing polypropylene fibers for making fabrics, ropes, and more.

Packaging Materials: Serves as raw material for various polypropylene packaging products such as bottles, containers, etc.

Plastic Products: Utilized in injection molding to produce various plastic items like barrels, pipes, household goods, etc.

Building Materials: Can be used to manufacture polypropylene sheets for applications in thermal and sound insulation in construction.

Why GN Separation Vacuum Pump?

The transport of polypropylene slurry poses challenges in terms of handling. Traditional pump technologies may encounter issues like blockage and pump damage when dealing with high-concentration polypropylene slurry. Therefore, the introduction of GN Separation solid vacuum pumps has become a solution.

- Efficient Operation: GN Separation’s solid vacuum pumps are renowned for their unique design and efficient operation. Their proprietary technology enables stable and efficient operation in the transportation of high-concentration slurry, reducing energy consumption and production costs.

- Anti-Clogging Design: The pump employs advanced anti-clogging technology, effectively addressing common blockage issues associated with traditional pumps when handling media containing solid particles, making it particularly crucial for polypropylene slurry.

- Reliability and Durability: GN Separation’s solid vacuum pumps use high-quality materials and advanced manufacturing processes, ensuring excellent reliability and durability even in harsh industrial environments, reducing downtime and maintenance costs.

- Versatility: The vacuum pump is designed to transport various materials, including solids, sludge, and liquids. It can meet the specific conveying needs of different industries.

- Low Maintenance: Due to its unique structure with no rotating parts in the chamber, GN vacuum pumps can operate in the harshest environments, resulting in low maintenance requirements and minimal wear and tear.

Intention to Purchase?

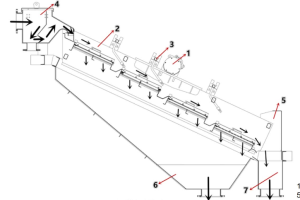

Our solids vacuum pumps are available in three models: GNSP-40B, GNSP-20B, and GNSP-10B, corresponding to different maximum conveying capacities of 40m³/h, 20m³/h, and 10m³/h, meeting various demands for different construction scenarios. Our vacuum pumps can be applied in industries such as:

- Slurry and vibration screen drilling cuttings removal

- Slurry and tailings, slurry pit cleaning

- Hazardous waste recovery

- Oil sludge, tank bottom cleaning

- Transportation of ship compartments

- Other powder transport

Our equipment is not limited to the aforementioned application scenarios. Their practicality, reliability, and efficiency are continuously being recognized by customers worldwide. If you need more information on feasible application industries, please feel free to contact our sales team right away!