In this article, we will

mainly talk about GN shale shakers with different treatment capacities,

different types of Shaker Screen for customer option.

1. GN Shale Shaker with different Treatment

Capacities.

As decided by different drilling rigs and

well depths, the needed drilling fluid volumes are also different. GN’s Shale

Shakers have different drilling fluid treatment capacities for customer option.

2. GN Shale Shaker with different types of

Shaker Screen.

As the necessary part of 1 complete shale

shaker, GN has many different types of shaker screen with high quality and competitive

price for customer option. Besides, the shaker screens that GN manufactures

could not only be used on GN’s shaker, but also could substitute most of the

screens made by other solids control companies on the global market.

If customer has the requirements for

substituting the other company’s shaker screen by using GN’s, it is just needed

to provide the specific dimensions, the mesh number, the original shape, and

the free samples could be sent for trying. The details are as below,

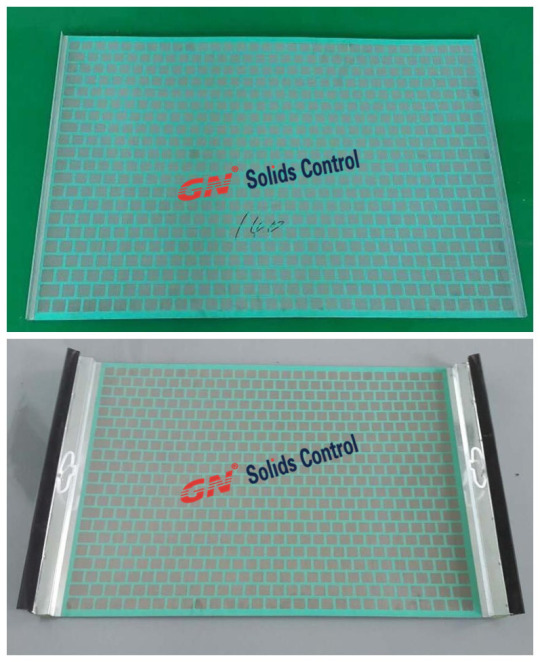

The steel frame screens are most applied to

the shale shaker. The screen frame adopts high-strength square steel tube welded

to multi-ribbed construction. They are sturdy and reliable. The screens are

constructed with 2 or 3 stainless steel layers bonded to a steel support plank.

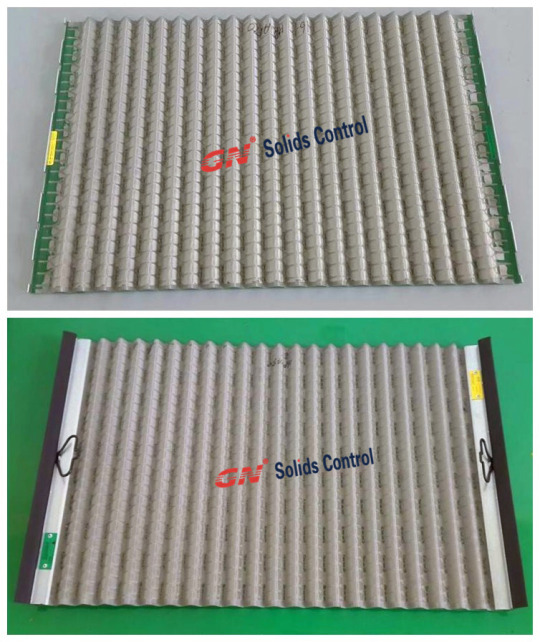

2.2. GN Pyramid Screen

This type of screen is the replacement

product of flat screen. The effective area is 125% to 150% of flat screens.

Without changing the construction of shakers, the using of the screens can

improve the quality of drilling fluid and increases the production. Screen has typical mesh cloth that appears

regular waves. And it can be mounted on suitable shaker by hookstrip or

wedge-shape fastening device. As compared to flat screens, this screen has

higher treatment capacity by reason of more useful area.