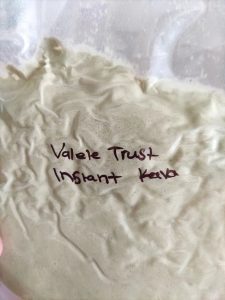

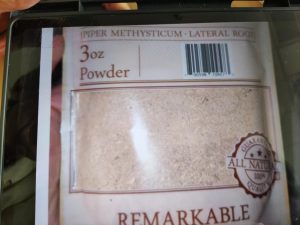

- Vanuatu KAWA project introduction

- Material details for the solid phase in the kava herbal solution, the feed should contain 93 to 95% water, and the discharged solid phase should have a humidity of about 85%.Feed 6.5 solid content, weight ratio, processing capacity 1-2K liters per hour, not sure whether the disc stack centrifuge separator machine can be used.

- The customer once again explained their processing process and the treatment effect they want to achieve. They don’t want the mud cake to be too dry, so they asked again about the angle of the half-cone angle.

- GN Two Phase Decanter Centrifuge Features of recommended model GNLW224ET

- Description of working principle

The bowl and screw of the decanter centrifuge rotate to the same direction with a certain differential speed. The material is continuously introduced into the screw shaft, and then flies to the bowl after its speed highly increased. Under the action of centrifugal force field, heavy solid phase is deposited on the bowl wall to form sediment layer. The solid is continuously pushed to the cone section of the bowl and discharged through the slag outlet. The light liquid phase forms an inner liquid ring, which is continuously overflow out of the bowl from the liquid outlets at the big end of the bowl Straight section of the bowl is the clarification area, and the cone section is the extrusion drying area.

2.2 T Series Decanter Centrifuge Features

The beach angle of the T Series dewatering decanter centrifuge is 8.5 Degree, which makes the decanter centrifuge cone section longer, that is, the drying and dewatering area of the decanter is longer, which is conductive to the dewatering performance of T series decanter centrifuge, and much drier solid cakes discharged. The beach angle of 8.5 degree will make the slag discharging more smooth so as to increase the amount of slag discharging.