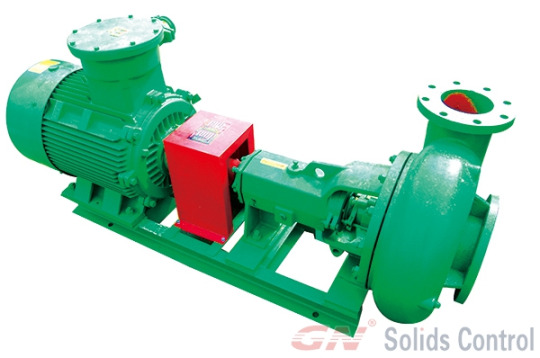

As we all known that a complete set of solids control system for oil and gas drillinf or for other kinds of drilling always includes desander cyclones and desilter cyclones which are not driven by motor or engine but with the high pressure of the drilling mud pumped into. So you will see normally there will be a centrifugal pump to deliver drilling fluids to the cones with a presurre in a tangent line so that the drilling fluids can rotate inside the cones, lighter liquid upward out through leading pipes, heavier solids downwards out through sand dischargeing channel. Beside desander and desilter cyclones, Hebei GN Solids Control also supplies centrifugal pumps specailly designed to deliver drilling fludis with the ablity to handle abrasive, viscous and corrosive medium, which are currently in operation for onland drilling and offshore drilling around the world. If comoared with other pumps, GN centrifugal pumps owns an excellent performance, handles large volums, bears high temperature, enjoys a long service life and easy maintenance.

The flow parts includes stuffing box, impeller, and housing assembly. These parts are poured from the highest grade of ductile iron, then finished to exacting specifications. After machining and inspection, these parts are processed through a quench and temper heat treating process to fully harden the parts throughout. During this process the parts are hardened to 40-44 ROCKWELL-C scale, this gives the "SB" parts the hardness to withstand the harshest pumping conditions. Look to the pumps for extended pump life. Besides delivering drilling fluids, GN centrifugal pump also can be used for mixing with the mud mixing hopper on the top. How many centrifugal pumps needed depends on the treating capacith of the solids control system, and the capacity of centrifugal pump should be matched to the capacity of desander and desilter.