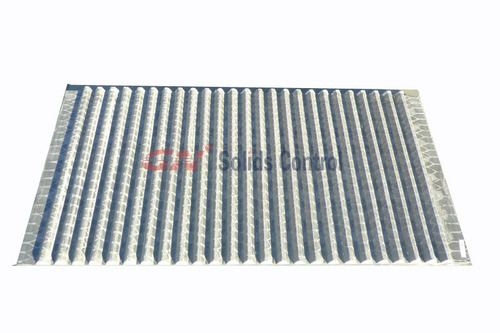

Several factors may contribute to premature shaker screen failure. Most failures result from improper screen installation or damage to the shaker itself. Cracked or warped shaker beds, which may result from many years of continuous use or improper maintenance, will cause poor vibration patterns. This may cause improper maintenance, will cause poor vibration patterns. This may cause improper solids conveyance, which in turn, may cause solids to agther on certain areas of screen, wearing holes in that ssection. Damaged bedgs may also affect the tensioning ability of the tension system, including flexure in the shale shaker screen.