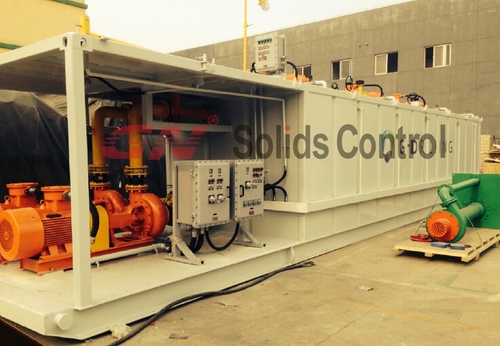

GN Solids Manage is world top manufacturer for drilling rig mud program for onshore and offshore drilling. GN exported quite a few complete 1000HP rig mud method for offshore drilling for a well-known offshore drilling company.

So that you can cater for distinct buyer calls for, GN offer diverse common proposal program for selection

Higher regular for 1000hp drilling rig mud method for onshore / offshore:

Full with 4 stage solids manage equipment and also the 5 stage separation:

1) Shale shaker 2 sets.

2) Mud cleaner with significant shale shaker, 1 set.

3) Vacuum degasser 1 set

4) Middle speed centrifuge & feed pump,1 set.

5) drilling waste management,1 set.

6) Jet mud mixer two sets

7) Necessary pumps, agitators and mud guns

Economic normal for 1000hp drilling rig mud program:

Comprehensive with 4 stage solids manage equipment as well as the 4 stage separation:

1) Shale shaker two sets

two) 1 set Desander 1 set, Desilter 1 set (without under flow shale shaker)

three) Vacuum degasser 1 set

four) Jet mud mixer 2 sets

five) Necessary pumps, agitators and mud guns

6) Tanks, attachments and electrical control panel for list equipment (for solution)

GN Solids Control also equip drilling waste management method together with drilling rig mud technique for onshore / offshore, for zero discharge. here we test it of GN drilling waste management in Europe,it’s good,Welcome you contact GN group for inquire,the test Result: http://www.mudcentrifuge.com/post/85199528086/gn-drilling-waste-management-along-with-solids, pls visit here.