1.Project introduction

The origin of the material is from sand in a wastewater flow

Material Temperature is 25 celicius & 28-29 celcius

The density of the material is Around 2000 kg/m3

The customer requested treatment capacity is 2-3 m3/h

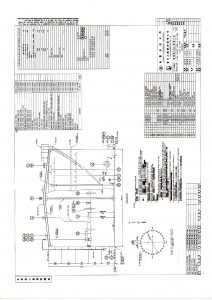

The height between the material and pump is 15 feet

The distance between the material and pump is 20 feet

The challenge and problem of the current situation is currently they use labor to take sand out from the forebay tank of the mini hydro power plant.

The process or equipment is being used on location at present and the performance now is they use manual labor, wheelbarrows, hoes and baskets to fill and take out sand from the forebay tank. The process takes one and half days to finish completely.

The project budget is about Rs. 3 million LKR.

- GN recommended sludge vacuum pump model is GNSP-10B.

2.1Brief introduction

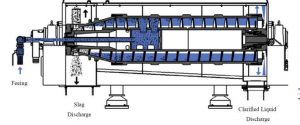

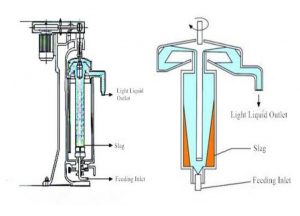

Sludge vacuum pump, also named as solids transfer pump. It is a type of pneumatic pump that sucks the material with vacuum produced by air operation, and then converts to positive pressure for discharging.Most of the solids, sludge and liquid could be transferred by using this pump. With special structure design of no rotating parts in the cavity, it can be used at tough environmental with high working performance and less maintenance. The pump can transfer material with high gravity and high density, solids content max.up to 80%. It has following features: the high efficiency venturi device can produce vacuum up to 25 inch HG(Mercury Column). This is equivalent to vacuum of 85Kpa to suck the material. The pump structure is simple and compact, almost none of wear parts. The transfer distance is up to 500-1000 meters.

2.2 Advantages of GN sludge vacuum pump.

Air operation, no need electric power, suitable for hazardous area application.

Powerful self-suction with long transfer distance. Suction distance up to 50 meters, discharge distance up to 500-1000meters.

Widely application for transferring liquid, wet sludge and solids.

Transferred solids size Maximum50 mm or 75 mm, sludge solids content up to 80%.

Compact structure for easy to move.

None of rotating parts inside the cavity, less wearing for long lifetime.

Automatically and continuously working is available with easy operation and maintenance.