In today’s fast-paced industrial landscape, efficiency and reliability are paramount, especially when faced with urgent demands. At GN Separation, we understand the critical nature of time-sensitive requirements, which is why we ensure a robust inventory of solid vacuum pumps to promptly meet our customers’ needs. Our solid vacuum pumps boast versatility, durability, and the flexibility to facilitate swift deliveries, making them ideal solutions for emergencies across various industries.

Understanding the Principles of Vacuum Pumps

Understanding the Principles of Vacuum Pumps

Before delving into the advantages of GN Separation’s solid vacuum pumps, let’s first grasp the fundamental principles behind their operation. Vacuum pumps are devices designed to remove gas molecules from a sealed volume, thereby creating a vacuum within that space. This process is crucial in numerous industrial applications where the absence of air or gas is necessary for optimal performance.

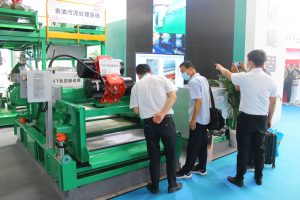

One common type of vacuum pump is the solid vacuum pump, which operates by mechanical means without the need for lubricating oil. This feature makes them particularly suitable for environments where oil contamination is undesirable, such as in food processing, pharmaceuticals, and semiconductor manufacturing.

Applications Across Industries

The versatility of solid vacuum pumps lends itself to a wide array of industries. In manufacturing, these pumps are indispensable for processes like vacuum packaging, degassing, and composite molding. Additionally, they play a vital role in research laboratories, where precise vacuum conditions are essential for experiments and analyses. Moreover, solid vacuum pumps find applications in environmental technology, wastewater treatment, and beyond, showcasing their adaptability to diverse operational requirements.

Materials and Corrosion Resistance

At GN Separation, we prioritize quality and longevity in our products, which is why our solid vacuum pumps are crafted from high-grade materials like stainless steel 304 and 316. These materials offer exceptional corrosion resistance, ensuring the longevity and reliability of our pumps even in harsh operating environments. Whether exposed to moisture, chemicals, or high temperatures, our pumps remain resilient, providing consistent performance over extended periods.

Introducing GN Separation’s Solid Vacuum Pump Models

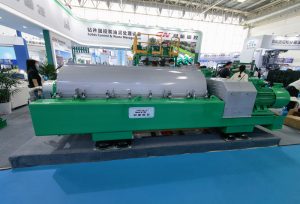

To cater to varying demands, GN Separation offers three distinct models of solid vacuum pumps:

- GNSP40B (40 cubic meters/hour): Ideal for high-capacity applications where rapid evacuation is necessary, the GNSP40B delivers exceptional performance and efficiency.

- GNSP20B (20 cubic meters/hour): With a balanced blend of capacity and versatility, the GNSP20B is suitable for a wide range of industrial processes, ensuring reliable vacuum performance.

- GNSP10B (10 cubic meters/hour): Compact yet powerful, the GNSP10B is perfect for applications where space is limited without compromising on vacuum pumping capabilities.

Meeting Urgent Demands with GN Separation

In times of urgency, having access to readily available equipment is invaluable. GN Separation’s extensive inventory of solid vacuum pumps enables us to promptly address our customers’ emergency requirements. Whether it’s a sudden breakdown or an unforeseen surge in production, our team is equipped to deliver efficient solutions with minimal downtime.

Conclusion

In conclusion, GN Separation’s solid vacuum pumps stand as reliable allies in the face of urgent industrial demands. With their robust construction, corrosion-resistant materials, and varied capacity options, these pumps offer unmatched versatility and performance across diverse applications. Whether you operate in manufacturing, research, or environmental sectors, our solid vacuum pumps provide the efficiency and reliability you need to thrive in today’s competitive landscape. Trust GN Separation to deliver timely solutions and meet your most pressing requirements with ease.