We are thrilled to announce that GN Separation has successfully sold two units of our screw press sludge dewatering machines, model GNDL402, to a European client. These machines represent the cutting edge of economic and environmentally friendly sludge dewatering technology.

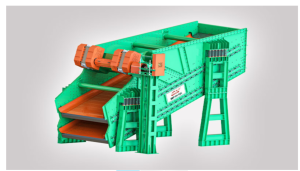

The GN Screw Press: An Overview

The GN screw press sludge dewatering machine is designed to be both cost-effective and environmentally friendly. It utilizes the principle of screw extrusion to achieve solid-liquid separation. This process is driven by the powerful squeezing force generated through the variation in screw diameter and pitch, along with the minute gaps between the floating and fixed rings. This innovative design ensures efficient dewatering by leveraging mechanical principles for superior results.

Key Features of the GN Screw Press

- Economic and Environmental Benefits: The GN screw press is engineered for minimal environmental impact and operational cost, making it an ideal choice for sustainable operations.

- Advanced Dewatering Technology: By using screw extrusion, the machine provides robust dewatering through changing screw diameters, screw pitches, and gaps between rings, ensuring effective solid-liquid separation.

- Automatic Control: Equipped with a fully automatic control cabinet, flocculation modulation box, sludge thickening and dewatering device, and liquid collecting tank, the GN screw press allows for continuous and automatic operation.

- Versatility: It is suitable for a wide range of sludge dewatering applications, including oily sludge treatment. The machine is designed to operate continuously and automatically without clogging.

ADVANTAGES OF THE GN SCREW PRESS DEWATERING MACHINE

- Wide Application Range: Suitable for various industries such as municipal sewage treatment, aquaculture, food processing, starch production, oil refining, pharmaceuticals, chemicals, paper production, and leather manufacturing.

- Continuous and Automatic Operation: Ensures consistent performance with minimal manual intervention and reduced risk of blockages.

- Cost Efficiency: Low investment and operational costs combined with no secondary pollution make it a financially sound choice.

- Energy Efficiency: Compact design and small footprint contribute to energy savings and environmental protection.

- Enhanced Sludge Treatment: Capable of dewatering sludge under aerobic conditions to prevent phosphorus release from anaerobic sludge dewatering.

Technical Details

The main body of the GN screw press dewatering machine consists of a filtration device composed of fixed and moving rings, with a screw axis running through them. The front section of the machine is dedicated to concentration, while the back section focuses on dewatering. As sludge progresses from the concentration section to the dewatering section, the filtering gap and screw pitch gradually decrease, enhancing the dewatering effect.

The rotating screw shaft not only transports the sludge but also drives the moving ring to clean the filtering gap, preventing clogging and ensuring continuous operation. This design enables effective dewatering by generating high internal pressure as the sludge volume is reduced.

Application and Customization

The GN dewatering screw press can handle sludge concentrations ranging from 2000 mg/L to 50000 mg/L. We offer a comprehensive range of sludge dewatering equipment, allowing clients to select the best solution based on their specific sewage treatment needs and budget. Additionally, GN provides integrated mobile sludge dewatering solutions tailored to customer requirements.

The sale of the GNDL402 screw press units to our European client marks another milestone for GN Separation. We are committed to delivering high-quality, efficient, and sustainable dewatering solutions to clients worldwide. For more information or to discuss how our equipment can meet your needs, please contact us. We look forward to future collaborations and are excited about the possibilities ahead.

Thank you for your interest in GN Separation.