1.Project Introduction

1.1 One High Speed tubular centrifuge for microalgae harvesting and one feed Peristaltic pump for treating capacity Volume: 900L and biomass concentration: ~30g/L (3%) microalgae size: ~4µm

1.2 Expected dryness of microalgae: After treatment, the moisture content in microalgae is about 30-40%

1.3 Expected volume of microalgae: The expected collection rate 95% or more, and solids larger than 2µm can be separated

1.4 5 times separation processes are required for 900L feed with above condition. Re: 5 times

How long is each separation process?

1.5 110 minutes for each separation process, including shutdown, dismantling to collect solids, cleaning drum about 50 minutes.

1.6 900L material will takes about 550 minutes in total.

1.7 The peristaltic pump tubing is made of silicone material, and it is estimated to be 1 year

2.GN Tubular Centrifuge model GNGQ142G introduction

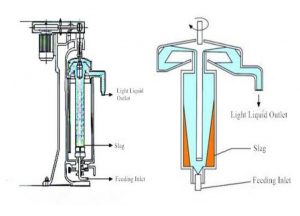

2.1 High Speed Tubular Centrifuge is a kind of fine separation equipment, which is especially suitable for the solid-liquid separation of suspensions with thin concentration, fine particles and small solid-liquid weight difference, or liquid-liquid-solid separation. It is necessary equipment for Industries of pharmaceutical, food, chemical, and biological products, fermentation broth, beverages, blood products, etc.

High Speed Tubular Centrifuges is artificial slag removal equipment, and the processing capacity is limited, so it is generally used for working conditions with low solid content and relatively small processing capacity.(GNGQ) Clarification Type Tubular Centrifuge

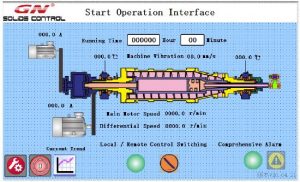

2.2 The centrifuge rotates at a high speed to reach a suitable working speed (the speed can be adjusted by the electric control panel), and the feeding inlet is continuously fed from the bottom, and a certain feeding pressure (greater than 0.05Mpa) is required.

The specific gravity of liquid phase in the feeding inlet is lighter, and it gradually spirals upward from bottom to top to continuously discharge from the clear liquid outlet at the upper part of the rotor.

2.3. The specific gravity of solid phase is relatively heavier, and it settles inside the rotor. After the solid is collected and full in the drum, the machine stops, and the rotor is manually removed for slag cleaning.

2.4. After the slag removal is completed, the rotor needs to be installed and reset, and then the next separation process begins.

This process can achieve solid-liquid separation.