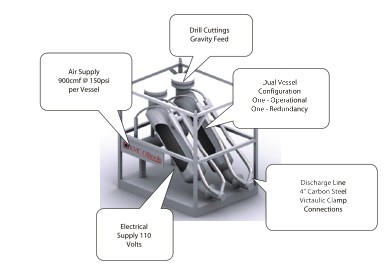

The slurry blowing pump (sbp) is designed to reclaim drilling fluid, sludges, and soids, transferring them on a continuous basis from one point on the drill rig to another. It can also be used for other waste stream spillages such as wastewater or slurries. The cleaning of ditches, cellars and sups plus the skimming of pips and cuttings boxes is also possible. Collected wastes are typically blown into a drilling waste container or alike.